Difference Between a Flammable Cabinet and a Normal Storage Cabinet

Many workplaces store paints, solvents, thinners, fuels, or cleaning chemicals in standard metal cupboards. But when it comes to storing flammable liquids, a normal storage cabinet is not the same as a flammable safety cabinet. Understanding the difference is critical for fire safety, legal compliance, and insurance protection.

Can You Store Flammable Liquids in a Normal Cabinet?

Short answer: No.

A standard metal storage cabinet is designed for organisation — not fire protection. It does not slow heat transfer during a fire, contain flammable vapours, provide spill containment, or meet hazardous storage requirements. In the event of a fire, a normal cabinet can rapidly heat up, causing stored liquids to ignite and intensify the fire.

What Makes a Flammable Cabinet Different?

A flammable cabinet is specifically engineered to reduce fire risk and contain spills.

Key differences include:

1. Double-Wall Construction

Flammable cabinets have dual steel walls with an insulating air gap that slows heat transfer during a fire.

Normal cabinets typically have single-wall construction.

2. Built-In Spill Sump

Flammable cabinets include an integrated liquid-tight sump which is 10% of the cabinets total storage volume as per SANS54470-1.

Normal cabinets do not provide secondary containment.

3. Self-Closing Doors

Many flammable cabinets feature automatic self-closing doors to prevent accidental exposure and seal the cabinet in the event of an emergency.

Normal cabinets rely entirely on manual closing.

4. Fire Resistance Performance

Flammable cabinets are tested to withstand fire exposure for a specified period (depending on model).

Normal cabinets are not fire-rated.

5. Ventilation Design

Flammable cabinets include ventilation ports, with flame arrestors to reduce ignition risks.

Standard cabinets do not account for vapour management.

Why This Difference Matters for Compliance:

In South Africa, hazardous chemical storage is governed by safety standards and the Occupational Health and Safety framework.

Using a normal storage cupboard for flammable liquids can result in:

Fire code non-compliance

Insurance claim rejection

Increased fire risk

Environmental liability

Personal accountability for safety officers and company owners

A flammable cabinet is not simply “stronger metal.”

It is a proactive safety measure.

When Is a Flammable Cabinet Required?

A flammable cabinet is typically required when:

Storing solvents, fuels, thinners, or alcohol-based chemicals

Quantities exceed minor-use thresholds (check local municipal bylaws)

Storage is inside a building

Ignition sources are present nearby

Risk assessments identify fire exposure potential

If in doubt, a formal site risk assessment should guide cabinet selection.

Final Thoughts

A normal cabinet organises.

A flammable cabinet protects.

The cost difference between the two is minor compared to the cost of a fire incident, failed audit, or rejected insurance claim.

If your facility stores flammable liquids, choosing the correct cabinet is not optional — it is part of responsible hazardous chemical management.

You can view our range of cabinets here.

If you are still unsure which cabinet will best suit your needs, contact us here.

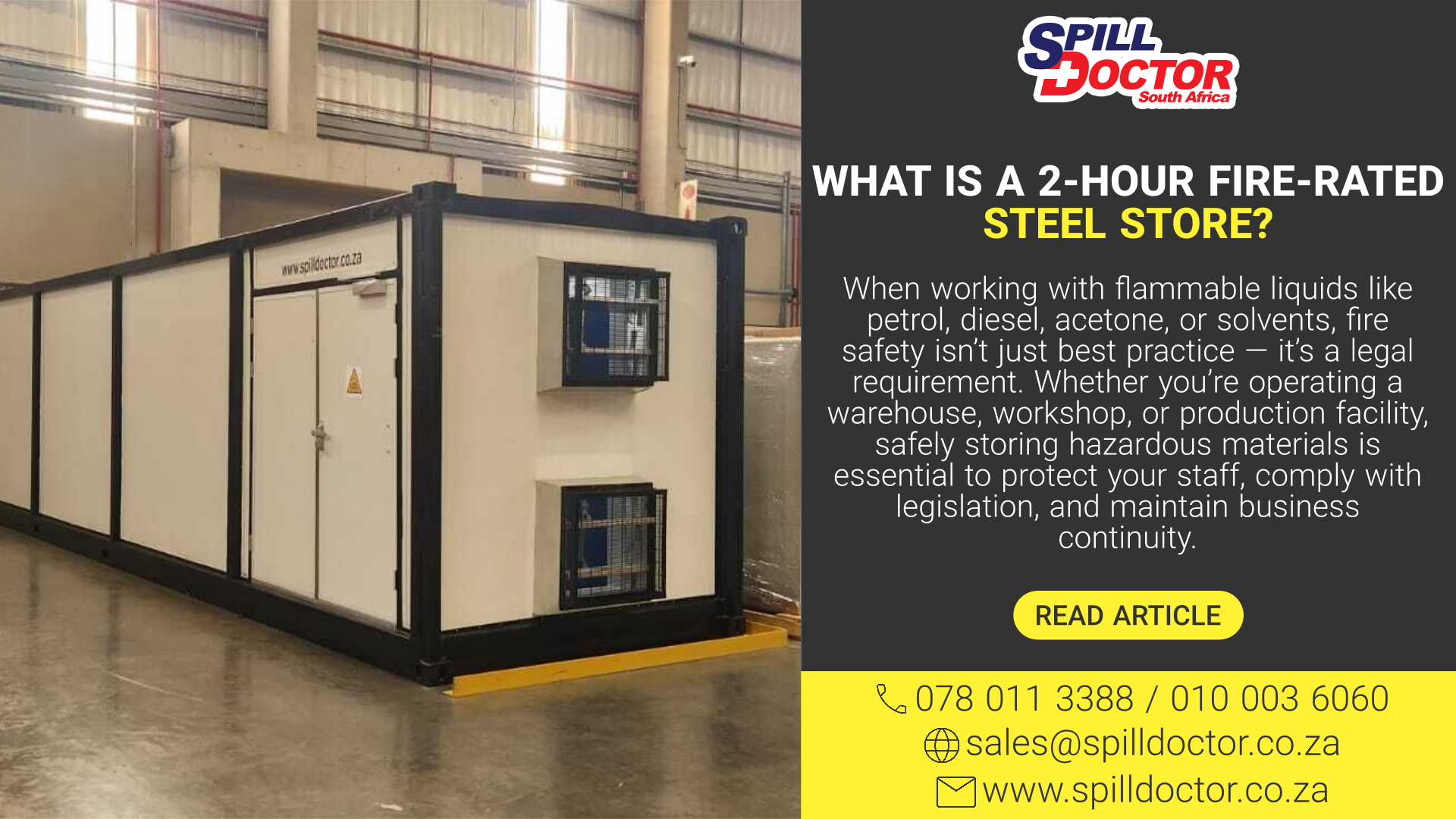

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?