What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?

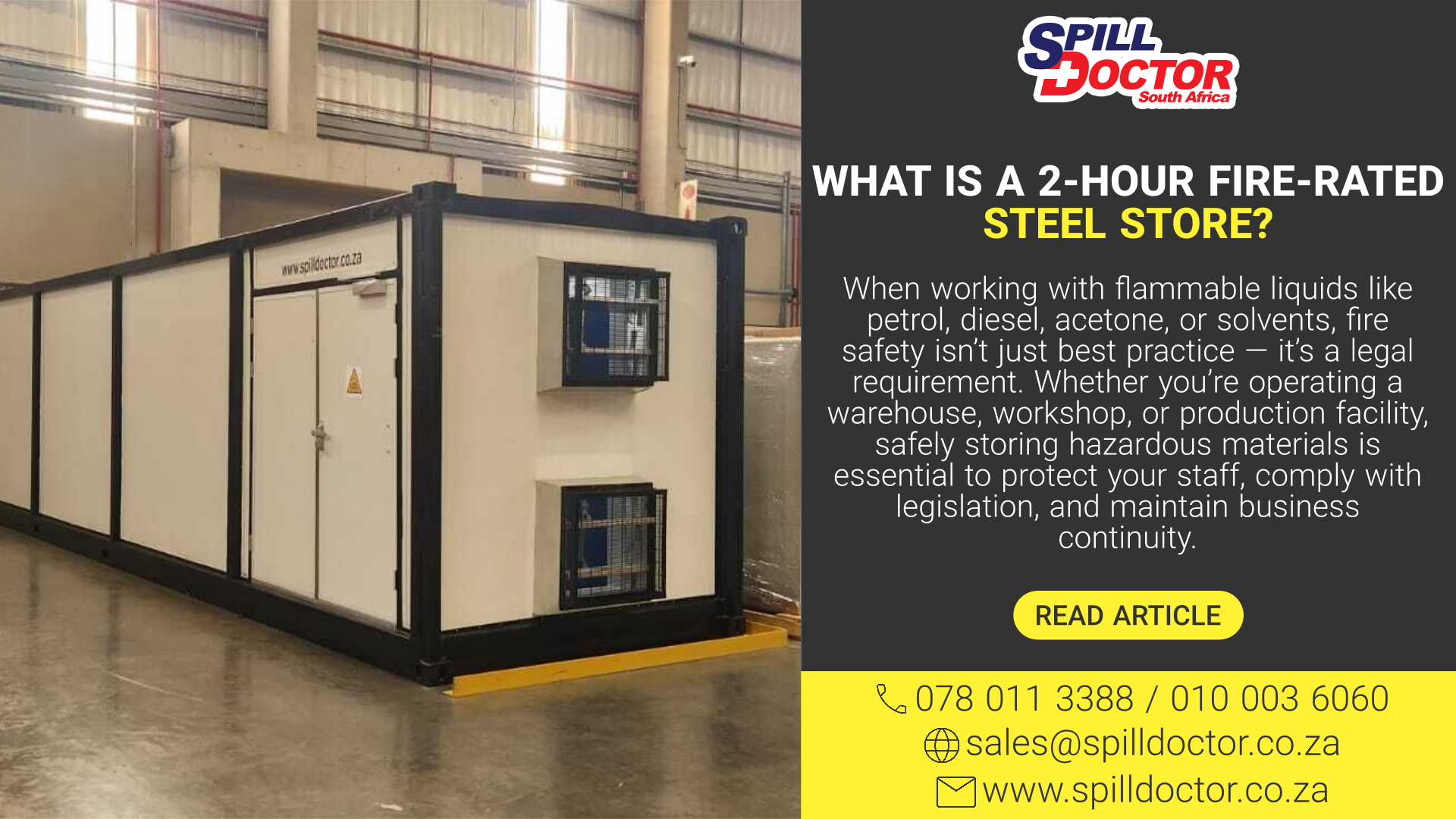

When working with flammable liquids like petrol, diesel, acetone, or solvents, fire safety isn’t just best practice — it’s a legal requirement. Whether you’re operating a warehouse, workshop, or production facility, safely storing hazardous materials is essential to protect your staff, comply with legislation, and maintain business continuity.

One of the most effective safety measures for flammable liquid storage is a 2-hour fire-rated steel store. But what exactly does “2-hour fire-rated” mean — and when is such a store necessary for your site?

What Does “2-Hour Fire-Rated” Actually Mean?

A 2-hour fire rating refers to how long a structure can resist fire exposure while maintaining its structural integrity and preventing internal temperature spikes. In this case, it means the steel store has been tested and certified to withstand fire conditions for 120 minutes.

This endurance is measured under standard fire test conditions, often simulating the heat curve of a structural blaze. During that time, the internal contents are protected against the full force of fire — giving emergency services time to respond and providing a crucial safety buffer for personnel evacuation.

In practical terms, it’s about containing the danger long enough to prevent disaster.

Legal Compliance: What South African Law Says:

In South Africa, the safe storage of flammable liquids is enforced under the General Safety Regulations (GSR) of the Occupational Health and Safety (OHS) Act. Specifically, GSR 4(2) states:

“No employer shall require or permit a flammable liquid to be used or applied other than in a room, cabinet or other enclosure specially constructed for this purpose of fire-resisting material or in a place which, owing to its situation or construction or any other feature or circumstance, is of such a nature that-

(a) no fire or explosion hazard is, can or may be created thereat…”

You can view the full legislation: here.

This means that if you’re storing more than minimal quantities of flammable liquids, especially indoors or near structures, a fire-rated store is likely required to meet compliance.

Failure to comply can not only result in penalties and shutdowns, but also puts your staff and assets at serious risk.

When Do You Need a 2-Hour Fire-Rated Store?

Not every situation demands a 2-hour fire-rated store, but many do. Here are typical scenarios where one is either strongly recommended or legally required:

- You’re storing bulk quantities of Class I or II flammable liquids (e.g., petrol, ethanol, acetone).

- The store is placed inside a building, rather than outdoors or in an isolated zone.

- There’s insufficient separation distance between the store and other structures, walkways, roads, or personnel.

- Your site is under strict insurance requirements or subject to a fire safety audit by local authorities or compliance officers.

In all these cases, a certified 2-hour fire-rated store offers peace of mind and may be the only acceptable solution under legal and insurance frameworks.

Features of a Compliant Fire-Rated Steel Store

A properly engineered fire-rated store isn’t just a steel box with thick walls. It incorporates a range of safety features that are essential for risk mitigation:

- Third-party certified 2-hour fire rating

- Built-in ventilation to prevent flammable vapour buildup

- Compliant sump to catch leaks or spills

- Reinforced, fire-resistant doors with secure locking

These stores are designed with both passive and active fire safety principles in mind — meaning they don’t just resist fire but actively help reduce the spread of flammable vapours and liquids.

Optional Add-Ons for Enhanced Safety

Depending on your application or risk profile, you may want to include custom options, such as:

- Zone 1 internal lighting

- Temperature control system

- Pushback racking systems for drums and IBCs

- Sprinkler system

- Extraction system for fumes

Why It Matters

Ultimately, fire-rated storage is about more than just ticking compliance boxes. It’s about:

- Protecting your people

- Preventing catastrophic damage

- Maintaining operational uptime

- Ensures long-term legal and insurance compliance

Even a small fire can escalate quickly when flammable liquids are involved. A 2-hour fire-rated steel store ensures that, in the worst-case scenario, your risk is contained, controlled, and mitigated. Often times an insurance company will not honor a claim in the event of a fire if flammable liquids were not properly stored.

Why Choose Spill Doctor?

At Spill Doctor, we supply fully compliant, third-party certified 2-hour fire-rated steel stores, designed for South African conditions and legislation. We offer:

- Full consultation and advice

- Customizable configurations

- Drawings and approvals assistance

- Turn-key solution from drawings to delivery

Whether you need a standard unit or a fully customized fire-rated enclosure, we’ve got a solution for you.

Need help choosing a compliant fire-rated store that suits your needs?

📞 Get in touch with us: here.

🛒 Explore our full range of 2-hour fire-rated stores: here.

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?