Why Proactive Safety Measures Are So Important

Workplace safety isn’t just about reacting to accidents – it’s about preventing them before they happen. Proactive safety measures involve planning, risk assessments, proper training, and using the right equipment to reduce hazards. According to industry research, up to 70% of workplace accidents could be prevented with proactive safety measures in place. This shows the real value of staying ahead instead of waiting for incidents to occur.

Proactive vs Reactive: A simple Example

Imagine two warehouses storing flammable liquids.

Reactive approach: A drum leaks unexpectedly, and the team scrambles to contain it with whatever materials they can find. Operations are stopped for hours, staff are exposed to unnecessary risks, and the company faces cleanup costs and potential compliance issues.

Proactive approach: A drum leaks unexpectedly, however the drum is stored on a complaint spill pallet, with appropriate spill kits places nearby, the staff are trained and act accordingly. This leak is contained before it becomes an issue. Operations are resumed within minutes, the properly trained staff were not exposed to unnecessary risk.

The Cost of Being Reactive

When companies wait for incidents to happen, the consequences can be severe. Injuries, production downtime, environmental damage, and regulatory penalties are just a few examples of what can occur from a lack of preparation. For instance, a chemical spill in a warehouse without proper containment could halt operations for hours, damage equipment, and disrupt workflow. These situations often create stress for employees and management, highlighting how reactive approaches can compromise both safety and efficiency.

Benefits of Proactive Safety Measures

Implementing proactive safety measures brings multiple benefits:

-

Reduced accidents and injuries – keeping employees safe and healthy.

-

Regulatory compliance – meeting legal requirements and industry standards.

-

Cost and time efficiency – minimizing disruptions and operational delays.

-

Improved workplace culture – showing employees their safety is a priority.

Beyond these tangible benefits, proactive safety measures help create a workplace where employees feel confident and supported. Organizations that invest in prevention foster a safety culture of responsibility, awareness, and accountability. Staff are more likely to follow safety protocols and report potential hazards, strengthening the overall safety environment.

Prioritizing proactive safety measures isn’t just a legal or operational necessity – it’s a commitment to your team and your business. By identifying risks, preparing for potential incidents, and encouraging a culture of safety, companies can prevent accidents before they happen, protect their employees, and maintain smooth, efficient operations. In today’s fast-paced industrial environment, prevention is not just better than reaction – it’s essential.

Spill Doctor offers a full range of spill control and hazardous storage solutions designed to keep you compliant and protected. Get in touch with us today.

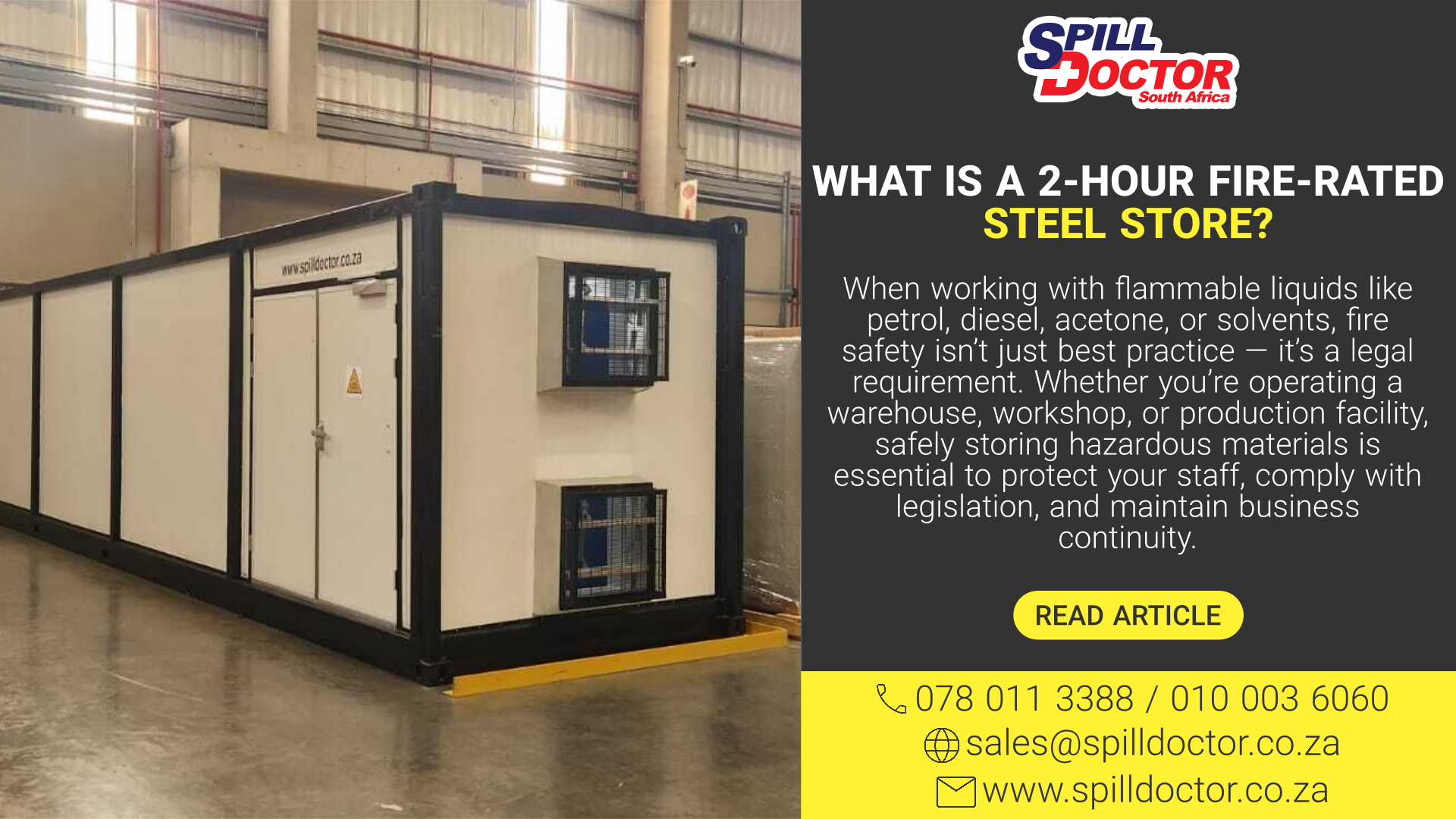

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?

What Is a 2-Hour Fire-Rated Steel Store – And Do You Need One?